M - X DYES

SHLOKKAZOL M-X TYPE SERIES SHLOKKAZOL M-X TYPE SERIES

|

|

|

|

|

|

|

Process Suitability |  |

Other Fastness | Light Fastness AATCC 16E | Post Fastness Properties | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

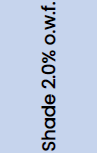

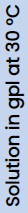

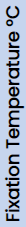

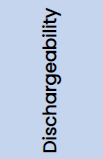

| Brill Yellow MX-8G | Yellow 86 |

asdfasdfasdfasdf

|

80 | M | H | 40 | S | NS | S | LS | Moderate | 4-5 | 4 | 4 | 3-4 | 3-4 | 4 | 4 | 3 | 3-4 | 4-5 | 4-5 |

| Yellow MX-4G | Yellow 22 | 65 | M | M | 40 | S | NS | S | LS | Good | 4-5 | 4-5 | 4 | 3-4 | 4 | 4 | 5 | 3 | 3-4 | 4-5 | 4-5 | |

| Golden Yellow MX-R | Yellow 44 | 150 | M | M | 40 | S | LS | S | LS | Poor | 4-5 | 4 | 3-4 | 3-4 | 3-4 | 4 | 4-5 | 3-4 | 4 | 4 | 4 | |

| Golden Yellow MX-3R | Orange 86 | 120 | H | M | 40 | S | LS | S | LS | Moderate | 4-5 | 4 | 3-4 | 4 | 4-5 | 4-5 | 4-5 | 3-4 | 4 | 4-5 | 4-5 | |

| Yellow MX-4R | Orange 14 | 150 | M | M | 40 | S | LS | S | LS | Poor | 4 | 4 | 3-4 | 3-4 | 4 | 4 | 4-5 | 3 | 3 | 4 | 4 | |

| Brill Orange MX-2R | Orange 4 | 65 | M | M | 40 | S | LS | S | LS | Poor | 4 | 4 | 3-4 | 3 | 3-4 | 3-4 | 4-5 | 3 | 3-4 | 4 | 4 | |

| Brill Red MX-5B | Red 2 | 80 | H | M | 40 | S | LS | S | LS | Poor | 4 | 3-4 | 3 | 3 | 3-4 | 3-4 | 4-5 | 3 | 3 | 4 | 4 | |

| Brill Red MX-8B | Red 11 | 70 | H | M | 40 | S | NS | S | LS | Poor | 4-5 | 3-4 | 3 | 3 | 3-4 | 3-4 | 4-5 | 2-3 | 3-4 | 3 | 3 | |

| Brill Magenta MX-B | Violet 13 | 70 | H | M | 40 | S | NS | S | LS | Moderate | 4 | 4 | 3-4 | 3-4 | 4 | 4-5 | 4 | 2-3 | 3 | 4-5 | 4-5 | |

| Brill Violet MX-4R | Violet 14 | 70 | H | M | 40 | S | NS | S | LS | Moderate | 4 | 4-5 | 4 | 3 | 3-4 | 3-4 | 4-5 | 4 | 3-4 | 4-5 | 4 | |

| Brill Blue MX-R | Blue 4 | 80 | H | M | 40 | S | LS | S | LS | Poor | 4-5 | 4-5 | 4 | 3-4 | 4 | 4 | 4-5 | 3-4 | 3-4 | 4-5 | 4-4 | |

| Blue MX-2R | Blue 81 | 70 | H | M | 40 | S | LS | S | LS | Poor | 4 | 4 | 3-4 | 3 | 3 | 3-4 | 4-5 | 3-4 | 3-4 | 4 | 4 | |

| Navy Blue MX-3R | Blue 9 | 70 | H | M | 40 | S | LS | S | LS | Moderate | 4-5 | 4-5 | 4 | 2-3 | 3 | 3-4 | 4-5 | 4 | 4 | 4 | 4 | |

H - High | M - Medium | L - Low | HS - High Suitable | S - Suitable | LS - Low Suitable | NS - Not Suitable

DYEING METHOD : EXHAUST DYEING

M:L Ratio - 1:10 | SALT & ALKALI REQUIREMENT

| DEPTH OF SHADE | SODIUM CHLORIDE OR GLAUBER SALT | SODA ASH | FIXATION (MINUTES) | |

| UNMERC. COTTON/KNITS | VISCOSE OR MERC. COTTON | |||

| Upto 0.10% | 10 | 7 | 10 | 30 |

| 0.11%-0.30% | 20 | 10 | 10 | 30 |

| 0.31%-0.50% | 30 | 20 | 15 | 30 |

| 0.51%-1.00% | 40 | 30 | 15 | 45 |

| 1.01%-2.00% | 50 | 40 | 20 | 45 |

| 2.01%-4.00% | 60 | 50 | 20 | 60 |

| >4.00% | 70 | 60 | 20 | 60 |

EXHAUST DYEING PROCESS DIAGRAM

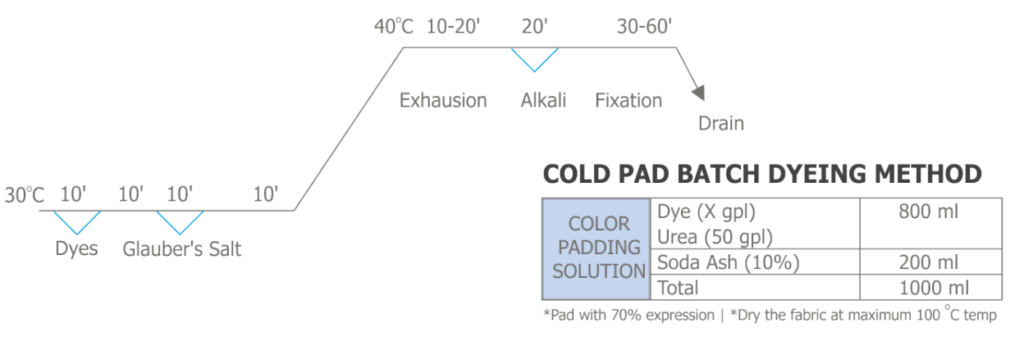

COLD PAD BATCH - DYEING PROCESS DIAGRAM

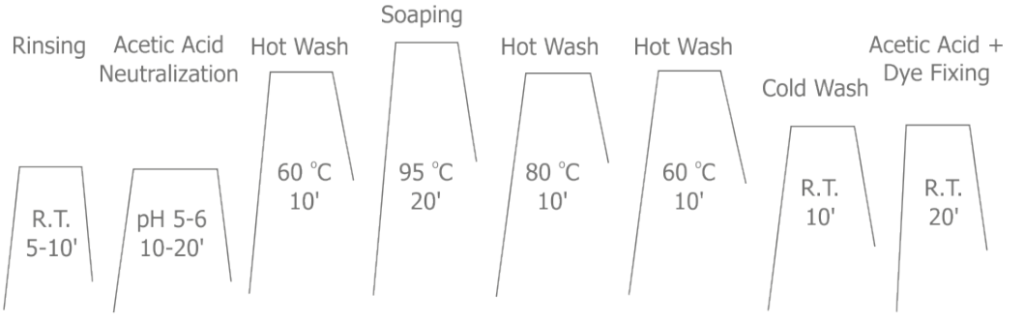

WASHING PROFILE

M-X DYES FEATURES

- HIGH COLOR FASTNESS: SHLOKKAZOL M-X DYES OFFER EXCEPTIONAL COLOR FASTNESS PROPERTIES, INCLUDING WASH FASTNESS, LIGHT FASTNESS AND PERSPIRATION FASTNESS. THIS MEANS THAT THE DYED FABRIC MAINTAINS ITS COLOR EVEN AFTER REPEATED WASHES, EXPOSURE TO LIGHT AND CONTACT WITH SWEAT.

- WIDE COLOR RANGE: SHLOKKAZOL M-X DYES ARE AVAILABLE IN A WIDE RANGE OF COLORS, PROVIDING TEXTILE MANUFACTURERS WITH A DIVERSE PALETTE TO CREATE VIBRANT AND APPEALING COLOR SHADES. THIS ALLOWS FOR GREATER CREATIVITY AND DESIGN POSSIBILITIES.

- GOOD LEVELING AND PENETRATION: SHLOKKAZOL M-X DYES HAVE EXCELLENT LEVELING AND PENETRATION PROPERTIES, ENSURING THAT THE DYE EVENLY SPREADS AND PENETRATES THE FABRIC. THIS RESULTS IN UNIFORM AND CONSISTENT COLOR DISTRIBUTION THROUGHOUT THE MATERIAL.

- HIGH COLOR YIELD: SHLOKKAZOL M-X DYES PROVIDE A HIGH COLOR YIELD, MEANING THAT THEY CAN ACHIEVE DEEP AND INTENSE COLORS WITH RELATIVELY SMALL AMOUNTS OF DYE. THIS TRANSLATES TO COST SAVINGS FOR MANUFACTURERS AS LESS DYE IS REQUIRED TO ACHIEVE THE DESIRED COLOR INTENSITY.

- ECO-FRIENDLY: SHLOKKAZOL M-X DYES ARE CONSIDERED TO BE RELATIVELY ECO-FRIENDLY COMPARED TO SOME OTHER TYPES OF DYES. THEY ARE WATER-SOLUBLE AND DO NOT CONTAIN HARMFUL HEAVY METALS. THIS MAKES THEM SAFER FOR THE ENVIRONMENT AS WELL AS FOR THE WORKERS HANDLING THE DYES.

- COMPATIBILITY WITH VARIOUS FIBERS: SHLOKKAZOL M-X DYES ARE PRIMARILY USED FOR DYEING CELLULOSIC FIBERS LIKE COTTON BUT THEY CAN ALSO BE USED ON OTHER NATURAL FIBERS SUCH AS LINEN, SILK AND WOOL. THEY FORM STRONG COVALENT BONDS WITH THE FIBER MOLECULES, RESULTING IN GOOD COLOR FASTNESS AND DURABILITY.

- EASY APPLICATION: SHLOKKAZOL M-X DYES CAN BE EASILY APPLIED TO TEXTILES USING VARIOUS DYEING TECHNIQUES SUCH AS EXHAUST DYEING, PAD-DRY-CURE OR PRINTING METHODS. THIS ALLOWS FOR FLEXIBILITY IN THE DYEING PROCESS AND EASE OF INTEGRATION INTO EXISTING MANUFACTURING PROCESSES.

- GOOD LIGHT AND HEAT STABILITY: SHLOKKAZOL M-X DYES EXHIBIT EXCELLENT STABILITY TO LIGHT AND HEAT. THIS MEANS THAT THE DYED FABRIC RETAINS ITS COLOR EVEN WHEN EXPOSED TO SUNLIGHT OR HIGH TEMPERATURES, ENSURING LONG-LASTING AND DURABLE COLORATION.